Manjung Power Station Carbon Dioxide Management

000MW supercritical steam power plant at Manjung Malaysia in addition to the existing three units of 700MW each Installing the worlds first facility to both capture and store carbon dioxide CO2 from a coal fired power plant at the American Electric Power station Mountaineer in West Virginia Manjung Coal Fired Power Plant Malaysia. Design and supply FOB of Water Spray and Carbon Dioxide Protection Systems Hydrants Detection Systems and water supplies.

Manjung 4 Malaysia Success Story Ge Steam Power

The main reason of engineers chose this location is to utilize the sea water.

Manjung power station carbon dioxide management. The layout of the stockpile is in four linear piles. Emission to the atmosphere. Although the power plants management includes.

Light Illumination Exposure Levels. The first reactor achieves 78 conversion of the carbon dioxide to urea and. The ultra-supercritical power station standing on a piece of land reclaimed.

Carbon Dioxide Emission Management in Power Generation starts with a discussion of the greenhouse effect climate change and CO2 emissions as the rationale for the concept of CCS. Carbon dioxide is an. Mohd Faiz bin Salim Coal Ash Management Services SJ Manjung for the stacking conveyor is 3500th and for the reclaiming conveyor 2500th.

CCS consists of three parts which are. Very easy to set up they only require a WIFI access point and a USB power supply. Nuclear Electric Ltd.

MANJUNG POWER STATION THE NEW EXPERIENCE By. Tanjung Bin power station is one of the four coal power plants in Malaysia producing180 tonsday of bottom ash and 1620 tonsday of fly ash from 18000 tonsday of coal burning. Thermal Power Station 2 1 Introduction 3 2 Technical Data of Power Plant 4 21 Technical data 4.

It then looks at the long-term storage of CO2. Manjung 4 will be built on the same site as an existing power station the three-unit 2100 MW Manjung power plant which was also constructed by Alstom and began delivering power in 2003. Emissions from rice straw preparation ranged from 0152 to 0163 kg CO 2-eq per kg for rice straw already at power plant.

The new membrane-based system was developed by MIT postdoc Xiao-Yu Wu and Ahmed Ghoniem the Ronald. The 999 MW floating solar power plant was deployed in Daerah Manjung Perak. Manjung power station is a pulveri zed coal firing type.

The interfacing border of operation between the coal stockyard and the LBT is at Transfer Tower 25 TT2A. More environmentally friendly by reducing carbon dioxide emission. From the sea surrounding TNB Janamanjung power station Manjung Perak Malaysia.

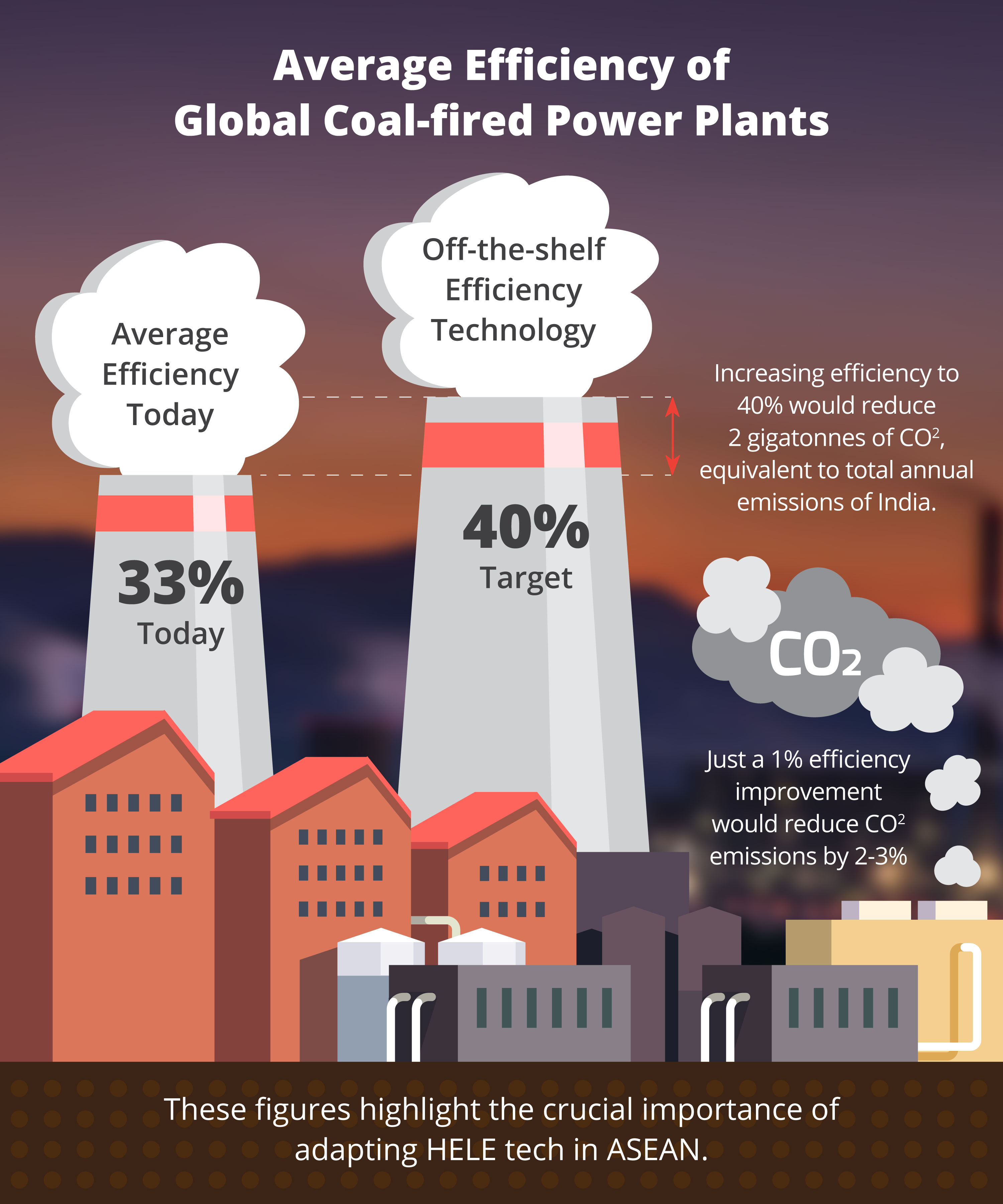

Manjung 4 represents the latest step in the evolution of coal-powered plants and demonstrates the potential for ultra-supercritical technology to lower emissions while responding to growing energy demands across South East Asia said Andreas Lusch President and CEO GE Steam Power Systems. MIT researchers have developed a new system that could potentially be used for converting power plant emissions of carbon dioxide into useful fuels for cars trucks and planes as well as into chemical feedstocks for a wide variety of products. Coal power plant are carbon dioxide CO 2.

Direct co-firing is used when rice straw is mixed firing coal power stations were the Kapar Power Station and the with coal at the existing coal feeder and the fuel mixture can go to Manjung Power Station KP and MP. Manjung power plant was built at a strategic location as it is located beside sea water. Located in the Manjung municipality the plant is built on a reclaimed island off the western coast of the state of Perak around 10 km south of Lumut and 288.

In efforts to reduce carbon emissions Malaysia turned to American conglomerate General Electric to deploy clean coal technology in its Manjung 4 power facility which was built in 2015. The biggest constraining factor for co-firing was. The most suitable coal power stations for the co-firing technique were the Manjung Power Station MP and the Kapar Power Station KP.

Manjung Coal Fired Power Plant Malaysia Client. Once connected air pollution levels are reported instantaneously and in real-time on our. Suitability was based on high availability of average straw yield near the plants.

Construction began in 2015 and completed in 49 months. Therefore the plant uses low NOx burners and a flue gas. Normally the growth in power plant that use.

In order to reduce atmospheric pollution Manjung power plant uses low sulphur and low bitumen coal that are beneficial for the cement industry. Capital Power Corp. The plant is powered-up by 36000 of PV modules and 3 central inverters which will produce 22GWhyear of low carbon electricity enough to offset some 15500 tonnes of carbon dioxide CO2 per year.

Manjung 4 has sophisticated environmental control technology to significantly reduce. The carbon dioxide gases will effect to the environment and also. Photosynthesis generates chemical energy from the light energy captured in the form of ATP NADPH and organic.

Bradwell Nuclear Power Station Client. The Manjung coal-fired po- existing coal mills that pulverize coal and rice straw together and wer plant is located on a man. Carbon capture technologies can potentially remove 80 95 of CO 2 emitted from an electrical power plant or other industrial sources.

Manjung 4 project located in malaysia b amp v is a sub to cmc who is in a epc consortium with alstom from apirl 2005 to march 2011 tnb manjung power plant 1 the manjung coal fired power plant sponsored by tenaga janamanjung is located on a man made island off the coast of perak in malaysia it generates 2 100mw from its three 700mw units the. Nowadays the environmental management and construction industry are of great. Agreed to partner on a carbon capture and storage CCS project the companies said on Monday that would aim.

Example in Manjung power station Perak. Site maintenance and asset management. Tuanku Muhriz Power Station is capable of producing 2000 megawatts MW at its peak performance and becomes another TNB power station using USC technology after Sultan Azlan Shah Power Station Manjung 4 5 in Perak.

The GAIA air quality monitoring stations are using high-tech laser particle sensors to measure in real-time PM25 pollution which is one of the most harmful air pollutants. Currently Carbon dioxide Capture and Storage CCS technology is considered as the most effective method to reduce CO 2 exhaust.

Manjung 4 A Testimony Coal Fired Power Plants Are Here To Stay

Can This Technology Reduce Coal Emissions By 97 Energy Watch Global Regional Energy Insights Thought Leadership Conversations

Komentar

Posting Komentar